Dual-ring radiant surface element on range not working video

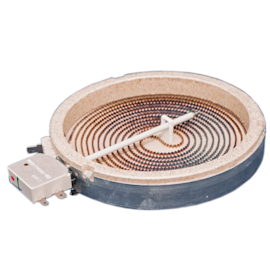

When a dual-ring radiant surface element—or dual burner—on your stovetop doesn’t work, one of three things has probably happened: the range has a bad element, a wiring problem or a broken surface element control switch. This Sears PartsDirect video walks you through the troubleshooting steps to help you figure out which part to replace to get the burner working again.

For more DIY help with your electric or gas range, check out our repair help page for troubleshooting tips and videos, repair guides and error code charts.

Hi, Wayne here from Sears PartsDirect. Today we’re going to help you figure out what’s wrong when a dual-ring radiant surface element—or dual burner—won’t work on your range.

Three failures can occur on a dual-ring element—the inner ring, the outer ring or both rings can fail to heat. A bad element, a wiring problem or a broken surface element control switch can all cause these failures.

In this video, I’ll guide you through the troubleshooting steps to help you find out which part failed.

Tools and supplies you may need

You’ll need a nut driver to remove the upper back panel. You also need a Phillips screwdriver and a sturdy prop such as a 2-by-4 piece of wood to prop open the cooktop. For electrical tests, you need a multimeter.

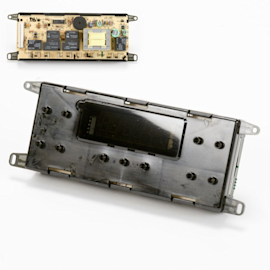

Check the surface element switch

First, let’s test the dual-ring surface element control switch in the control panel.

Unplug the range and pull it forward so you can get to the back. Remove the screws from the upper back panel and pull it off.

Take a picture of the wires connected to the switch so you’ll know how to reconnect them later. Then pull off the wires one by one.

The surface element switch has 5 spades that supply current to the element. The spades are labeled P1, P2, 2, 4 and 4a.

Here’s how the element switch works.

The P1 and P2 spades receive electric current. When you turn the burner knob to heat the inner ring of the element, internal switch contacts first send current from P1 to 2 and from P2 to 4. Then wires connected to spades 2 and 4 carry current to the element and the inner ring heats.

When you turn the burner knob to heat both rings of the element, a switch contact sends current from P1 to 2, just like for heating the inner element. In addition, internal contacts send current from P2 to spades 4 and 4a. Then, the wires connected to 2, 4 and 4a carry current to the element and, voila, both rings heat.

So, let’s check these internal switch contacts using a multimeter to see whether the element switch is okay.

Turn the control knob to the position that heats both rings of the element. We’ll do 3 resistance checks with the knob in this position. If the switch works, the multimeter will read 0 ohms for all three checks. If the meter reads OL for any check, replace the surface element control switch.

So let’s get checking.

With your multimeter set to measure resistance, check the internal switch contact P1 to 2 by touching one meter lead to P1 and the other meter lead to 2.

Next check resistance from P2 to 4.Then check P2 to 4a.

If any checked OL, you can skip the next round of checks, because you know you need to replace the switch.

If those 3 checks all had 0 ohms readings, turn the control knob to the position for heating just the inner ring of the element. Check resistance from P1 to 2 and then from P2 to 4. If either of those connections read OL, replace the surface element control switch.

If the switch is okay, the next step is to check the element and its wiring.

Check the surface element and its wiring

To check the surface element and its wiring, we’ll test resistance through the wires that carry current from the element switch to the element itself: spades 2, 4 and 4a. On this range, the element’s orange wire connects to spade 2 on the switch, the orange/black wire connects to spade 4, and the purple/orange wire connects to spade 4a. Wire colors on your dual-ring element may differ, but you can use the same basic procedure to check the wires.

Two resistance checks through these sets of wires will determine whether the element and its wiring are okay.

For the first resistance check, touch one meter probe to the orange wire and the other meter probe to the orange/black wire and note the meter reading. For the second check, keep the meter probe on the orange wire and move the other meter probe to the purple/orange wire and note the meter reading.

If the dual-ring element isn’t heating at all and the multimeter measured resistance between 20 and 100 ohms during both checks, the element and the wiring between the element and the switch are okay. That means a problem with the supply wiring is preventing the element from heating. If you want to skip to that section, look for the slide titled “Check the Element Switch Supply Wiring.”

If the multimeter measured OL during either of these checks, you have to figure out if it’s the surface element itself that’s the problem or the wiring between the switch and the element. So we’ll check resistance directly at the element to see what caused the OL reading.

Test the surface element

To get to the dual-ring surface element, open the oven door and remove the screws from the bottom of the front lip of the cooktop frame. Move the oven door out of the way. Carefully pull the cooktop slightly forward to release the front lip of the cooktop frame from the front cabinet support bracket. Raise the front of the cooktop slightly to release the frame sides from the front support bracket and then pull the cooktop forward to release the hinge tabs from the slots in the backguard.

Lift the front edge of the cooktop and place a prop where it's steady, so the cooktop won't fall. Don’t damage the insulation when propping open the cooktop, or you’ll have to replace it.

Take a picture of the wires connected to the dual-ring element so you’ll know how to reconnect the wires later.

Carefully pull the orange, orange/black and purple/orange wires off the element spades.

Two resistance checks through these sets of wires will determine whether the element is okay.

For the first resistance check, touch one meter probe to the orange wire’s spade and the other meter probe to the orange/black wire’s spade. For the second check, keep one probe on the orange wire’s spade and touch the other meter probe to the purple/orange wire’s spade.

A measurement of OL during either test means you need to replace the surface element.

A reading of between 20 and 100 ohms during both tests means the element is okay but there’s a broken wire between the switch and the element—in that case, replace the wires.

If both checks had an OL reading and you have an older range, check the parts diagram for your range to see if the thermal limiter is sold separately.

If it is, test whether the thermal limiter or the element failed. Refer to the wiring diagram for your range and check resistance through the thermal limiter.

If the reading is OL, replace the thermal limiter. If the reading is 0 ohms, replace the element.

Check the switch supply wiring

If the dual-ring element isn’t heating at all, the element switch is okay and you measured 20 to 100 ohms through the element wires that connect to the element switch, a break in the supply wiring going to the element switch is preventing the element from heating.

The supply wires for this dual-ring element connect to the supply wires for the left rear element. If the left rear element is working, it means the failure is in the black/orange wire or the red wire between the left rear element and the dual-ring element.

Take a picture of the wires connected to the left rear element control switch so you’ll know how to reconnect them later. Then pull the black, black/orange and red wires off the switch.

First, check the black/orange wire. Measure the resistance between the end of the black/orange wire that connects to the left rear element and the end that connects to the dual-ring element switch. If the wire is okay, it measures near 0 ohms. A measurement of OL means the wire is broken, so either replace the wire harness or find and repair the break in the black/orange wire going to the control switch.

If the black/orange wire is okay, measure the resistance between the end of the red wire that connects to the left rear element and the end that connects to the dual-ring element switch. If the wire is okay, the multimeter measures near 0 ohms of resistance. If not, find and repair the break in the red wire or replace the wire harness.

Whew, you’re done. Reconnect the wires to the surface element control switches and element using your photos as a guide, then reassemble the range.

We hope this video helped you out today. Check out our other videos here on the Sears PartsDirect YouTube Channel. Subscribe and we'll let you know when we post new videos.

Symptoms for electric ranges

Main causes: impact from dropping an item on the glass surface, ceramic glass surface flaw, surface element temperature …

Main causes: faulty surface element, burner control switch failure, temperature limiter not working properly, loose wiri…

Repair guides for electric ranges

How to replace a range radiant surface element

If the element on your glass cooktop isn't heating up even though it gets power, replace it yourself, in about 45 minute…

How to replace an electric range oven control board

If the electronic oven control board isn't powering the bake and broil functions, you can replace it in less than half a…

How to replace a range coil surface element

Easily replace a coil surface element in 15 minutes or less by following these step-by-step instructions.…

Articles and videos for electric ranges

Learn about the differences between cooking on gas and electric stoves.…

Learn about all the convenient features on our Sears PartsDirect website that make your parts purchases easier.…

Get answers to frequently asked questions about Sears and Sears PartsDirect.…