Snowblower engine won't start: troubleshooting tips video

This video from Sears PartsDirect shows what to check if your snowblower engine won’t start, including basic maintenance like how to replace your spark plug and fuel filter, along with more advanced troubleshooting, such as checking continuity, engine compression and valve lash.

Check out our snowblower repair help page for more troubleshooting guidance and step-by-step repair instructions.

Tools and parts needed

Hand tools

Fresh gasoline

Compression gauge

Multimeter

Work gloves

Check the snowblower gas, fuel filter and fuel line

Hi, this is Wayne with Sears PartsDirect. Today, we're going to talk about troubleshooting a snowblower that won't start. If your snowblower isn’t starting, there are a few things you can do to get it back into good working order.

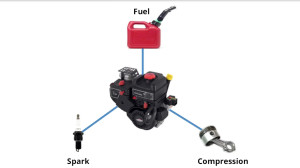

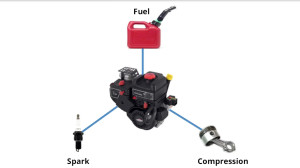

For an engine to start, you need fresh, clean fuel, a spark and the right amount of compression in the engine.

First, let’s talk about fuel. Use extreme care when handling gasoline. Work in a well-ventilated area free of open flames or sparks.

Fresh, clean fuel is a must. Old gas absorbs moisture when it sits for a long time in your gas tank or your gas can. Drain the fuel tank and fill it back up with fresh fuel if the gas is more than 6 months old. You can also use a fuel stabilizer to help keep your gas fresh.

Dirty gas can clog the fuel filter in your tank, so you’ll also want to take a look and replace it if it’s old or clogged. Most owners' manuals recommend changing the fuel filter at the start of every season. Here’s a video that will show you how to change your fuel filter.

While you're replacing the fuel filter, it's a good idea to disconnect the fuel line from the carburetor and the fuel filter and inspect it for damage. Take a look at the fuel line and make sure there are no cracks and that it's still flexible and soft. Replace the fuel line if it's cracked or broken. Here's a video showing you how.

Test the spark plug and ignition system

Next, we'll talk about engine spark. The spark plug is the ignition source for the fuel in the engine. Spark plugs should also be replaced once a season.

If you know your spark plug is from last year, you probably want to replace it. Here’s a video to show you how to replace and set the gap on a spark plug.

If you know your spark plug is good, and your engine still won’t start, then you need to check the ignition system. Pull the spark plug wire off the spark plug and connect it to a spark plug tester. Connect the spark plug tester wire to the spark plug. With the start key in the switch, pull the starter rope and check for a spark in the spark plug tester.

If the ignition system produces a spark through the tester then you can move on to checking compression.

Check the stop switch

If you don't see a spark though the tester, then a defective stop switch in the ignition system could be preventing your plug from sparking. Let’s check the stop switch using a multimeter.

Remove the tester, but leave the spark plug wire disconnected. Remove the belt cover. Then remove the two bolts securing the gearbox bracket and move it aside to access the muffler cover bolts. Remove all six bolts and pull the cover off. Then remove the wires from the stop switch. Set your meter to measure continuity and place the meter probes on the stop switch leads.

You should measure "no continuity" though the stop switch with the start key inserted. On this meter, that’s a 1 in the far left corner.

If you measure continuity through the stop switch with the key inserted, replace the stop switch. This video will show you how.

If the stop switch is okay, you’re going to want to have a service technician check the position of the ignition coil and adjust the air gap if necessary. The ignition coil may need to be replaced if the air gap is correct.

Check cylinder compression

Now let’s move on to checking engine compression. After you get everything put back together, remove the spark plug from the cylinder. Pull the starter rope several times to purge any fuel or oil from the cylinder.

Make sure the compression meter reads 0 and if it doesn’t, release the pressure inside the meter. Install a compression gauge in the spark plug hole. Pull the starter rope repeatedly, until the needle on the gauge stops rising.

You should measure between 40 and 60 psi of compression. If your pressure is out of that range, you may need to adjust the valve lash. This video will show you how.

If the valve lash adjustment doesn’t solve your problem, you could have a stuck valve, or several other engine issues. Have a service technician check that out.

Hey thanks for watching. Check out the other videos here on the Sears PartsDirect YouTube channel, and don't forget to subscribe.

Symptoms for gas snowblowers

Choose a symptom to see related snowblower repairs.

Things to do: replace the spark plug, change the oil, rebuild the carburetor, adjust valve lash, adjust or replace the b...

Main causes: clogged chute, damaged auger blades, broken shear pins, worn auger belt, damaged gear case, engine problems...

Main causes: dirty carburetor, stale fuel...

Main causes: punctured tire, damaged rim...

Main causes: dirty carburetor, clogged fuel filter, dirty spark plug, incorrect valve lash, leaky engine gaskets...

Main causes: stale gas, clogged carburetor, clogged or broken fuel line, dirty spark plug, bad rewind starter, incorrect...

Main causes: loose drive clutch cable, damaged drive clutch cable, worn friction disc, scraper blade scraping the ground...

Main causes: snow build-up in chute, chute drive mechanism failure, bad chute control assembly...

Main causes: clogged chute, snow build-up in auger housing, broken auger shear pins, auger drive belt needs adjustment, ...

Repair guides for gas snowblowers

These step-by-step repair guides will help you safely fix what’s broken on your snowblower.

How to adjust snowblower engine valve lash

Adjust the engine valve lash on your snowblower to keep the engine starting and running smoothly....

How to adjust snowblower skid shoes

To prevent snowblower auger and shave plate damage, adjust the skid shoes regularly to keep the shave plate ¼-inch high....

How to replace a snowblower shave plate

Follow the 7 easy steps in this repair guide/video to replace a worn out shave plate on your snowblower....

Articles and videos for gas snowblowers

Use the advice and tips in these articles and videos to get the most out of your snowblower.

Get an overview of the main steps in a snowblower tune-up and click to videos with more details....

Get your snowblower ready for winter before winter arrives, so you don't have to mess with it while snow piles up....

Protect your snowblower's engine and body by preparing it for after-season storage....