How to replace the motor coupler on a top-load washer

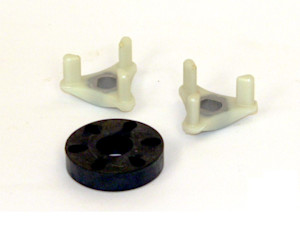

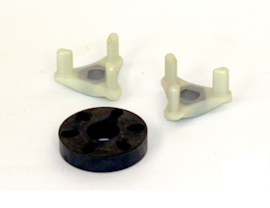

This DIY washer repair guide explains how to replace the motor coupling on a top-load washer. The washing machine motor coupler is a flexible coupling on the motor shaft connection to the direct-drive transmission. If the drive system seizes up, the coupling breaks to protect the drive motor from damage.

How to know if your washer's motor coupler is bad

If the washing machine motor coupler isn’t working, you’ll notice one or more of these symptoms:

The washer fills with water and drains, but won't agitate or spin even though the drive motor runs.

The motor buzzes when the motor is running.

You smell burning rubber or plastic when the motor runs.

If the washer fills and drains but doesn't agitate or spin, replace the motor coupler with part 285753A.

Direct-drive washers that use the motor coupler covered in this repair guide are made by Kenmore, Whirlpool, Maytag, Estate, Crosley and Roper.

If you're not sure if your top-load washer is a direct-drive washer, check out our washer FAQs to learn how you can tell.

This video explains how to replace a motor coupler on a direct-drive top-load washing machine.

Instructions

- 01.

Shut off the electricity

Unplug the power cord from the wall outlet.

Wear work gloves to protect your hands.

- 02.

Open the control console

Pull the plastic end caps off the sides of the control console.

Remove the screws at the base of the control console.

Pull the control console slightly forward and then swing it up and back over the top of the back panel.

Tip: Some models have the screws on the back of the end caps instead of on the front of the control console. Other models have spring clips under the end caps instead of screws. Remove the rear screws or use a putty knife to release the spring clips.

PHOTO: Remove the plastic endcaps from the control console.

PHOTO: Remove the screws at the base of the control panel console.

PHOTO: Flip the console up and back.

- 03.

Remove the cabinet

Unplug the wire harness from the lid switch on the washer’s top panel.

Release the clips that secure the cabinet to the washer’s back panel. Using a slot screwdriver, pry the clips forward to release the clips from the slots in the top panel.

Lift the back of the cabinet and slide the cabinet forward to remove it from the washer frame.

Set the cabinet out of the way.

PHOTO: Unplug the lid switch wire harness connector.

PHOTO: Insert a screwdriver to pry the clips forward.

PHOTO: Release the cabinet clip.

PHOTO: Remove the washer cabinet from the frame.

- 04.

Release the drain pump

Use a slot screwdriver to release the metal mounting clips that secure the drain pump to the front of the drive motor.

Pull the drain pump forward to release it from the drive motor shaft. Leave the hoses connected to the drain pump.

Move the pump to the side of the motor so it’s out of your way while you replace the motor coupler.

PHOTO: Release the drain pump clips.

PHOTO: Move the drain pump to the side of the motor.

- 05.

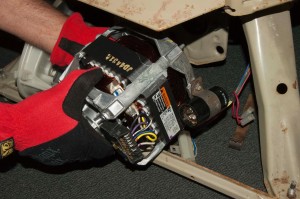

Remove the drive motor

Release the locking tab on the wire harness connection plug and detach the wire harness from the drive motor.

Detach the wires from the drive motor capacitor.

Remove the screws from the drive motor retainer clips.

Release the bottom clip using a slot screwdriver and then remove the bottom clip.

The drive motor is heavy. Place one hand under the drive motor to support the motor and prevent it from falling as you remove the top retainer clip. Release the top retainer clip and pull the drive motor off.

Warning: The drive motor is heavy. Use a helper if necessary to remove the drive motor.

PHOTO: Unplug the motor wire harness.

PHOTO: Detach the wires from the drive motor capacitor.

PHOTO: Remove the screws from the motor retainer clips.

PHOTO: Remove the bottom motor retainer clip.

PHOTO: Support the motor and release the top motor retainer clip.

PHOTO: Pull the drive motor out.

- 06.

Remove the old motor coupler

Pry the remnants of the old motor coupler from the motor shaft and transmission shaft and clean any residue from the shafts.

Tip: Use a crescent wrench to carefully pry the motor coupler cog off of the drive motor shaft.Warning: Significant force may be required to remove the motor coupler cogs from the drive motor shaft and the transmission shaft. Use caution when prying the cogs from the shafts.

PHOTO: Pry the cog off of the motor shaft.

PHOTO: Pull the cog off of the transmission shaft.

- 07.

Install the new motor coupler

Carefully push one of new motor coupler cogs onto the transmission shaft. Tap the cog into place using the handle of a slot screwdriver and a hammer until the end of the transmission shaft is flush with the outer surface of the cog base.

Install the black rubber isolator on the transmission cog.

Carefully push the remaining motor coupler cog onto the motor shaft. Tap the cog into place using the handle of a slot screwdriver and a hammer until the drive motor shaft is flush with the outer surface of the cog base.

Tip: Install both cogs of the new motor coupler even if only one of the cogs of the original motor coupler was broken. Also install the new isolator even if the original isolator doesn’t appear to be damaged.

PHOTO: Install the new motor coupler cogs.

- 08.

Reinstall the drive motor

Position the upper drive motor clip so that it can be snapped into place to hold the drive motor once the motor and transmission are properly engaged through the motor coupler.

Line up the drive motor cog pegs with the holes in the isolator on the transmission shaft.

Carefully push the drive motor into place so the cog pegs on the drive motor shaft fit correctly into the holes in the isolator on the transmission shaft.

Hold the drive motor in place with one hand and reinstall the top metal motor mounting clip with the other hand. The top motor mounting clip helps hold the motor in place while you reinstall the bottom motor mounting clip.

Reinstall the bottom motor mounting clip.

Reinstall the screws in the motor mounting clips.

Reattach the wires on the drive motor capacitor.

Plug the wire harness back into the connector on the drive motor.

PHOTO: Push the drive motor into place.

PHOTO: Reinstall the bottom motor retainer clip.

PHOTO: Reinstall the motor clip screws.

PHOTO: Reattach the drive motor capacitor wires.

PHOTO: Plug the drive motor wire harness back in.

- 09.

Reinstall the drain pump

Rotate the shaft of the drive motor so it’s properly orientated with the receptacle in the drain pump.

Push the drain pump back onto the shaft of the drive motor so it’s properly engaged.

Secure the drain pump with the metal mounting clips.

- 10.

Reinstall the cabinet

Position the cabinet in front of the washer.

Tilt the back of the cabinet up slightly and keep the front lip of the cabinet on the floor. To position the front lip under the washer frame, push the base of the cabinet forward with your foot to slide the front lip of the cabinet under the front base of the washer. Then lower the back of the cabinet so the holes in the back of the sides of the cabinet engage the alignment tabs at the back of the sides of the washer base.

Reinstall the spring clips at the top of the cabinet.

Plug the lid switch wire harness back into the receptacle on the top panel of the washer.

PHOTO: Reinstall the cabinet.

PHOTO: Reinstall the spring clips at the top of the washer cabinet.

PHOTO: Plug in the lid switch wire harness.

- 11.

Reinstall the control console

Flip the control console down and position it properly on the top panel of the washer.

Reinstall the mounting screws at the base of the control console.

Snap the plastic end caps onto the sides of the control console.

PHOTO: Reinstall the control console screws.

- 12.

Restore the power

Plug the washer into the electrical outlet.

Most common symptoms to help you fix your washers

Choose a symptom to see related washer repairs.

Main causes: unbalanced load, loose spanner nut, worn drive block, broken shock absorber or suspension spring, debris in…

Main causes: bad lid switch or door lock, bad timer or electronic control board, wiring failure, bad water inlet valve a…

Main causes: clogged drain hose, house drain clogged, bad drain pump, water-level pressure switch failure, bad control b…

Main causes: leaky water inlet valve, faulty water-level pressure switch, bad electronic control board…

Main causes: water heater failure, bad water temperature switch, faulty control board, bad water valve, faulty water tem…

Main causes: lack of electrical power, wiring failure, bad power cord, electronic control board failure, bad user interf…

Main causes: no water supply, bad water valves, water-level pressure switch failure, control system failure, bad door lo…

Main causes: worn agitator dogs, bad clutch, broken motor coupler, shifter assembly failure, broken door lock, suspensio…

Main causes: broken lid switch or lid lock, bad pressure switch, broken shifter assembly, faulty control system…

Repair guides for top-load washers

How to replace the clutch assembly in a top-load washer

If the washer spins when the basket is empty but not when the basket is full, the problem could be the clutch assembly. …

How to replace the motor coupler on a top-load washer

If the washer drains but won’t agitate or spin, the motor coupler might have broken to protect the drive motor from dama…

How to replace the gear case in a top-load washer

If the washer won't spin or agitate with the motor running, replace the gear case, following the steps in this repair gu…

Effective articles & videos to help repair your washers

Use the advice and tips in these articles and videos to get the most out of your washer.

Find tips for using your washing machine efficiently to save energy and help reduce utility bills.…

Learn about all the convenient features on our Sears PartsDirect website that make your parts purchases easier.…

Get answers to frequently asked questions about Sears and Sears PartsDirect.…