Lawn mower won't start troubleshooting video: fuel, ignition and compression problems video

A clogged air filter, bad spark plug or contaminated gas can prevent your walk-behind lawn mower from starting. Troubleshoot the problem with this Sears PartsDirect video, which shows how to check engine compression, clean the fuel line and look at the choke linkage, return spring and carburetor.

Check out our DIY Walk Behind Mower Repair page for more troubleshooting videos, repair guides and answers to commonly asked questions.

Today we’re talking about some troubleshooting steps to figure out why your lawn mower won’t start. Although your mower might look different from this Craftsman 21-inch mower, they all work pretty much the same.

These are the tools and supplies you might need, depending on the problem.

Tools and equipment needed

Starting fluid

Fresh gasoline

Ratchet and deep socket

Spark plug tester

Compression gauge

Shop rag

Fuel-safe container

Pipe cleaner

Carburetor or carburetor rebuild kit

Fuel, spark and compression

Since we’ll be working around gasoline, choose a well-ventilated area free of open flame or sparks.

For an engine to start and run when you pull the recoil starter rope, it needs 3 things. The first is fuel, which is a combination of gasoline and air that mixes in the carburetor. Then it needs a spark from the spark plug to ignite that fuel in the cylinder. Finally, it needs the right amount of compression in the cylinder to drive the piston. To fix your problem, we’ll have to figure out which of these three is missing.

We’re going to start by checking a few easy things.

Check the air filter

A clogged air filter can keep air from getting to the carburetor and mixing with the gas.

Remove the air filter cover and pull out the air filter. This mower has a pleated paper filter, but yours might be a different type of paper filter, or it might be foam. If you have a paper filter that’s just a little dirty, you can tap the filter on a hard surface to clean it. If it’s completely clogged, then you need to replace it. If your mower has a foam air filter, you can find cleaning instructions in your owner’s manual.

Check for a fuel problem

While the air filter is removed, let’s do a quick test to see if the engine has a fuel problem. Spray starting fluid through the air filter opening to the carburetor and then try to start the engine.

If it doesn't start, that eliminates a fuel problem, leaving spark and compression on our list of suspects. If the engine starts and runs briefly, click here to skip to the section about diagnosing fuel problems.

Spark plug and compression

Check the spark plug first. Pull off the spark plug wire and remove the spark plug, using a ratchet fitted with a deep socket. Look for carbon or oil buildup on the spark plug electrode that could prevent sparking. Also, look for a crack in the ceramic insulator. If you see excessive buildup or a crack, replace the spark plug.

If the spark plug looks good, reinstall it and then connect a spark plug tester to check the ignition system. Release the rope from the mower handle so it's in reach when testing the spark plug. Connect the tester boot to the spark plug and connect the spark plug wire to the other end of the tester. Clamp the bail control bar down to release the blade brake. Pull the starter rope and see if the tester sparks. If the tester shows that there’s no spark, follow the steps in our video about troubleshooting the ignition system.

If the spark plug is good and the ignition system works, check the cylinder compression. You need a compression gauge for this test.

First, remove the spark plug from the cylinder and pull the starter rope several times to purge fuel or oil from the cylinder. Insert a compression gauge in the spark plug hole and push the button to zero-out the gauge. Pull the starter rope repeatedly, until the needle on the gauge stops rising. The gauge should measure between 40 and 60 psi of compression. If it’s lower than 40 psi, have a service technician examine the engine and fix the compression problem. The technician has the right tools and the expertise to diagnose low compression.

Testing the gas, tank

Now, if the engine started and ran briefly when you did the starting fluid test, you know the spark and compression are okay and the problem is in the fuel system. For these tests, be sure you’re in a well-ventilated area where gas fumes can’t build up.

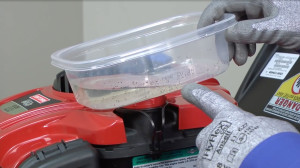

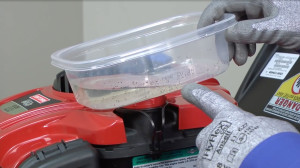

First, let’s look at the condition of the gas. Old gas that has absorbed water or gas that has dirt in it can keep a mower from starting. If your gas has been sitting around a while—either in the tank or in the can—drain the tank and fill it with fresh, clean gas from a clean gas can.

In the future, if you're going to leave gas in the tank for a while, add fuel stabilizer.

To drain the tank, lay a shop rag on the mower deck below the tank to catch spills. Place a clean, durable container under the fuel line connection on the bottom of the tank. Release the fuel line clamp and pull the fuel line off to drain the gas into the container. For information on disposing the gas safely and legally, check with your local fire department or hazardous waste recycling center.

If you find debris in the drained gas, check for a contaminated fuel tank. Use a flashlight to look inside the tank for grass or debris. If you see debris, release the rope from the mower handle and then remove the three screws from the lower housing. Remove the blower housing and pull the tank off the engine. Rinse out the tank with water and let the tank dry completely before reassembling the mower. Don’t pour that water down a drain. Dispose of it correctly along with the old gas.

Checking the filter screen, fuel Line

After rinsing out the fuel tank, check the filter screen at the bottom of the gas tank for damage. On this style of engine, the screen isn’t available as a separate part, so if the screen is damaged, you have to replace the tank. Some tanks have a removable fuel filter that you can clean or replace. Check your owner's manual for more information.

You should also check the fuel line for a crack or clog. Disconnect the other end of the fuel line from the carburetor. Examine it for cracks or cuts and replace it if it’s damaged. If you don’t see any damage, look through the fuel line and clear any clogs with a pipe cleaner.

Determining carburetor issues

If you’ve ruled out the quality of the gas and the fuel line, it’s time to turn to the carburetor, which mixes gas and air that is drawn into the cylinder.

Let’s start with the carburetor choke plate. The choke plate controls the ratio of gas and air sent to the carburetor depending on engine temperature. The engine on a lawn mower that’s been idle for more than an hour is cold and needs less air to start. In this case, the choke plate should close to temporarily restrict airflow through the carburetor so more fuel can enter the cylinder.

A choke plate that’s stuck open could prevent the cold engine from starting. Check the choke plate by looking through the carburetor air inlet on the air filter base. The choke plate should be fully closed. If the choke plate is open, check the choke thermostat and linkage. First, remove the air filter base to access the choke linkage and choke thermostat. Remove the blower housing if you didn't already remove it to rinse out the fuel tank.

Examine the choke linkage and return spring to see if they're connected properly and moving freely. Reconnect the choke linkage and return spring and replace any broken parts. If the choke linkage and return spring looked good, then your choke thermostat is likely stuck. Replace the choke thermostat if it's stuck in the open position.

Instead of a choke plate, some engines have a primer bulb that you press to force more fuel into the cylinder when starting a cold engine. Replace the primer bulb if it's damaged.

Replace or rebuild carburetor

If the choke plate or primer bulb work, it’s likely you need to replace or rebuild the carburetor. Here's a video that shows you how to replace the carburetor.

Or, you could rebuild the carburetor, which takes more effort but costs less. Order the carburetor rebuild kit and then clean and rebuild the carburetor if you want to save money on parts. Here's a video that shows how to rebuild the carburetor.

Once you restore the fuel flow to the engine cylinder by replacing or rebuilding the carburetor, the engine should start.

I hope that this video helps you out today. Be sure to check out our other videos, here on the Sears PartsDirect YouTube Channel, and subscribe if you like them.

Symptoms for gas walk-behind mowers

Choose a symptom to see related walk-behind mower repairs.

Main causes: damaged cutting blade, loose cutting blade, damaged flywheel key, engine needs tune up…

Main causes: uneven wheel height settings, damaged wheel, dull or damaged cutting blade…

Main causes: engine needs tune up, dirty or clogged carburetor, damaged flywheel key…

Main causes: drive control cable failure, worn or broken drive belt, bad transmission, broken drive wheel…

Main causes: stale gas, engine needs tune up, bad spark plug, dead battery, bad recoil starter, faulty safety switch, ba…

Main causes: dirty carburetor, bad spark plug, clogged air filter, engine choke problems, clogged gas cap vent…

Repair guides for gas walk-behind mowers

These step-by-step repair guides will help you safely fix what’s broken on your walk-behind lawn mower.

How to rebuild a lawn mower carburetor

The carburetor mixes air with fuel to drive the piston. Rebuild the carburetor if it's clogged or leaks.…

How to replace a lawn mower recoil starter on an OHV engine

Replace the recoil starter if it doesn't move when you pull the starter rope.…

How to replace a lawn mower wheel

Learn how replace a damaged wheel on a walk-behind lawn mower—it's a quick, easy fix.…

Articles and videos for gas walk-behind mowers

Use the advice and tips in these articles and videos to get the most out of your walk-behind lawn mower.

Learn about all the convenient features on our Sears PartsDirect website that make your parts purchases easier.…

Get answers to frequently asked questions about Sears and Sears PartsDirect.…

A blade obstruction, bad recoil starter or locked-up engine can prevent the pull cord on your mower from working. See ho…